Electromechanical pad printing machine for many applications

Your advantage:

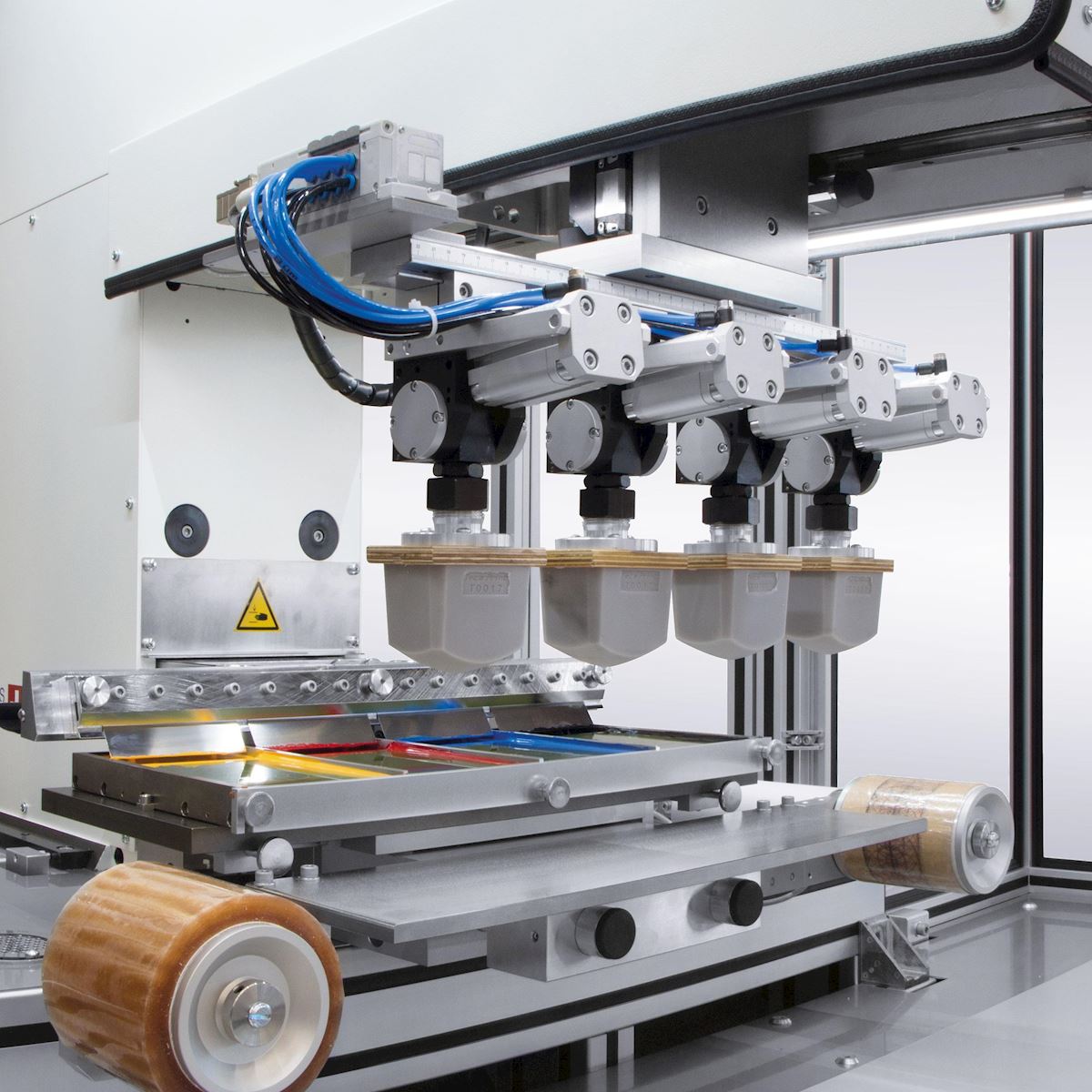

- 1 to 5 colours

- highest flexibility for your printing process

- servo drive control

- suitable for many applications

- open inkwell system

- a wide range of peripheral devices, accessories and software options available

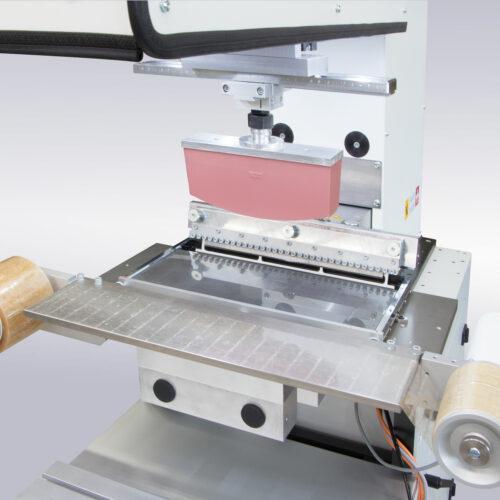

The pad printing machine TPX 300 with an open inking system is driven by three servo motors. This offers a highly flexible printing process. The operation can be controlled via the user-friendly colour touch-screen.

Between the plate holder, adjustable in x- and w-axes and the pad stroke, which is infinitely variable horizontally and vertically, the TPX 300 is fully adjustable in all directions without the need of additional adjustment devices.

Additional characteristics of the TPX 300 are a spacious, flexible working area, an increased printing force and a very high print accuracy. An integrated pad cleaning device is available, that offers a maximum use of the cleaning tape thanks to the cleaning offset function.

Technical data

- Colors: 1 to 5 colours

- Plate sizes:

standard plate widths: 250 / 350 / 450 mm

standard plate depths: 100 / 120 mm - Output: up to 1’600 cycles per hour

- Drive system:

electromechanical (3 axis control with 3 servo-motors),

infinitely adjustable parameters - Printing force: 4000 N (printing force has to be balanced)

- Mains connection: 230 V / 50 Hz, 5 – 6 bar air pressure

- Air consumption: 0.04 litres / cycle at 6 bar

- Control: PLC – HMI touchscreen

- Vertical pad stroke:

electromechanical, 160 mm infinitely ajustable - Cliché plate adjustment:

± 5 mm (x-axis), ± 2° (rotation) - Weight:

approx. 245 kg without base

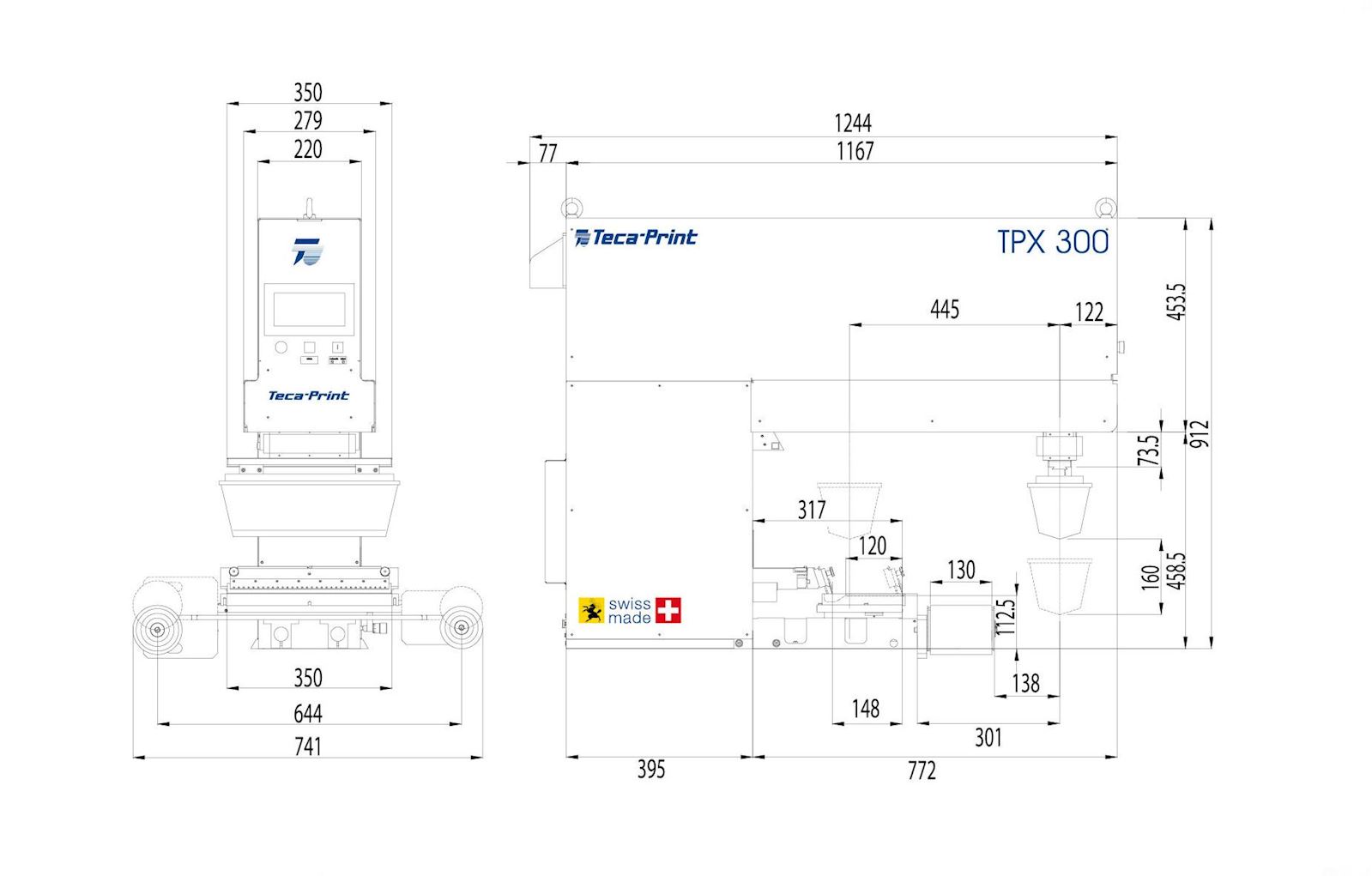

approx. 410 kg with MS 352 machine base - Dimensions (WxHxD): 740 x 955 x 1’244 mm (dimensions without base)

Wijzig taal

Wijzig taal