High-performance pad printing machine

for integration into systems

Your advantage:

- electromechanical, servo drive control

- cycle times of up to 2’800 cycles per hour

- perfectly suitable for integration into systems

- sealed inkwell system

- 1 colour

- increase of process reliability by options such as cliché plate cooling or temperature compensation

- ink cup sizes of up to Ø 180 mm

The TPM 161 electromechanical pad printing machine was created for integration into systems. Equipped with a modern PLC controller and an external control panel with a colour touchscreen display, the TPM 161 will satisfy the most demanding applications.

As an option, the TPM 161 can be controlled via a bus system. With a printing force of almost 4000 N and a printing capacity of 2’800 pieces per hour, the TPM 161 pad printing machine underlines its ability to perform within integrated print system settings. A pad cleaning device with a tape width of 100 and 150 mm, as well as the TI 300 thinner injection unit are available as options.

Technical data

- Colors: 1 color

- Ink cup sizes:

Ø 72 mm, Ø 96 mm, Ø 130 mm, Ø 160 m, Ø 180* mm

*overlapping ink cup - Plate sizes:

100 x 220 mm to max. 190 x 350 mm - Output: up to 2’800 cycles per hour

- Drive system: electromechanical

3 axis control with 3 servo motors, infinitely adjustable parameters - Printing force: 4000 N (printing force must be balanced)

- Mains connection: 230 V / 50 Hz, 5 – 6 bar air pressure required for some pneumatic accessories

- Control:

PLC – HMI touchscreen, option of interface connection via data bus system possible - Vertical pad stroke:

electromechanical, 160 mm infinitely adjustable - Cliché plate adjustment:

± 2° (rotation) - Weight:

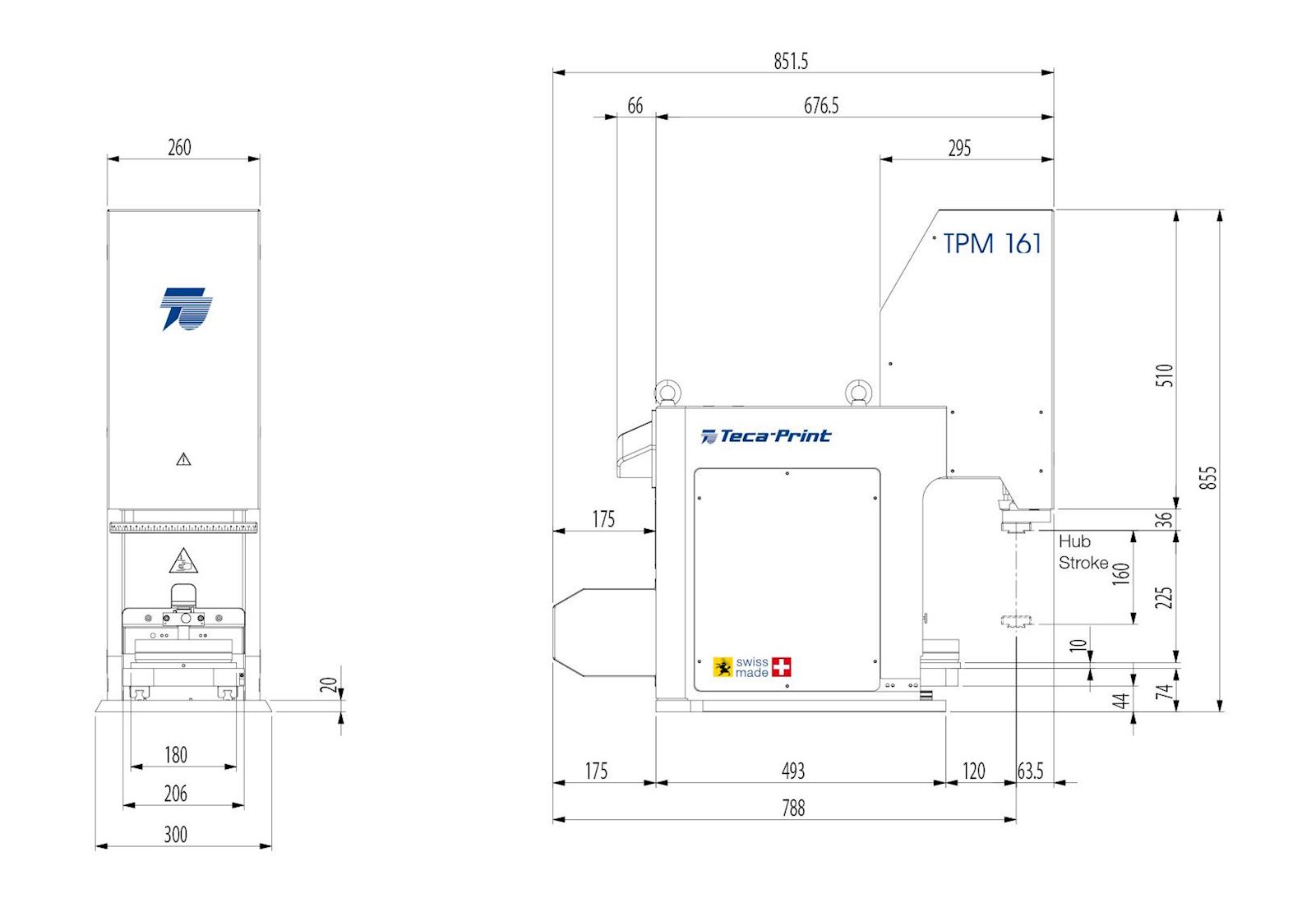

approx. 127 kg without base - Dimensions (WxHxD): 300 x 855 x 852 mm

Wijzig taal

Wijzig taal