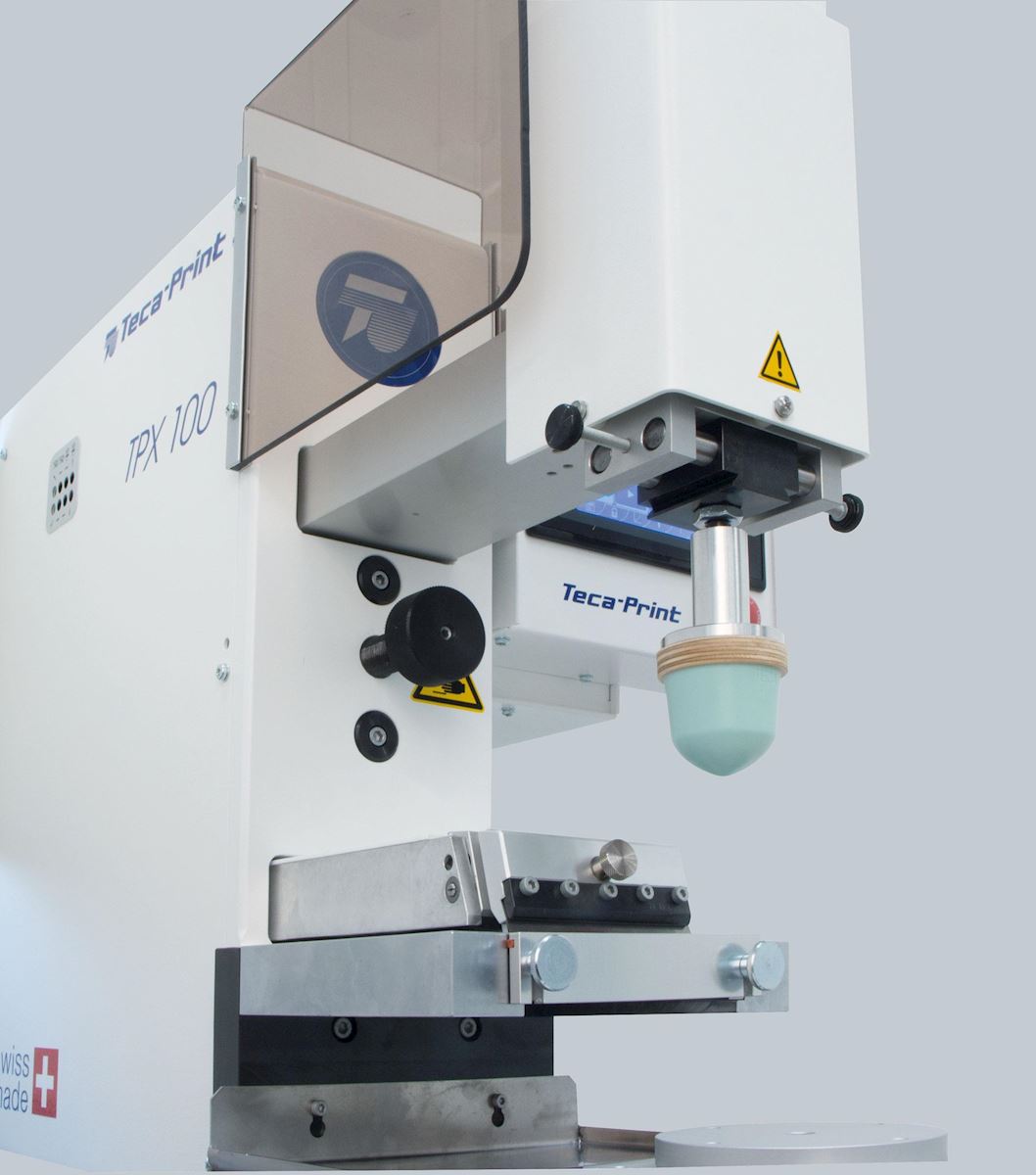

High-precision pad printing machine for demanding quality prints

Your advantage:

- 1 or two colours

- highest precision and accuracy

- electropneumatical

- compact design

- open inkwell system

- available as “édition cadrans”

The TPX 100 pad printing machine with open inking system impresses as a small, compact machine with high-precision printing performance and modern PLC control.

The TPX 100 is therefore used wherever the best performance is required for smaller print formats. Highest printing and repeat accuracy are a matter of course for the electro-pneumatically driven machine, which is often used as a manual workstation.

A coloured touchscreen enables clear, user-friendly operation.

An extensive range of peripheral equipment is available for the TPX 100, such as the automatic thinner injection, a rotary table or shuttle table, a pad sliding device, etc.

The TPX 100 can of course also be combined with various accessories such as a machine base or coordinate table.

Technical data

- Colors: 1 or 2 colors

- Plate sizes:

standard plate width: 80 / 100 / 130 mm

standard plate depths: 80 / 100 mm - Output: up to 1’800 cycles per hour

- Drive system: electropneumatical

- Repeat accuracy:

< ± 0.02 - Printing force: 250 N (printing force has to be balanced)

- Mains connection: 230 V / 50 Hz, 5 – 6 bar air pressure

- Air consumption: 0.5 litres / cycle at 6 bar

- Control: PLC – HMI touchscreen

- Vertical pad stroke:

100 mm, 140 mm as special edition, electrical infinitely adjustable - Outreach pad carriage:

88 mm - Weight:

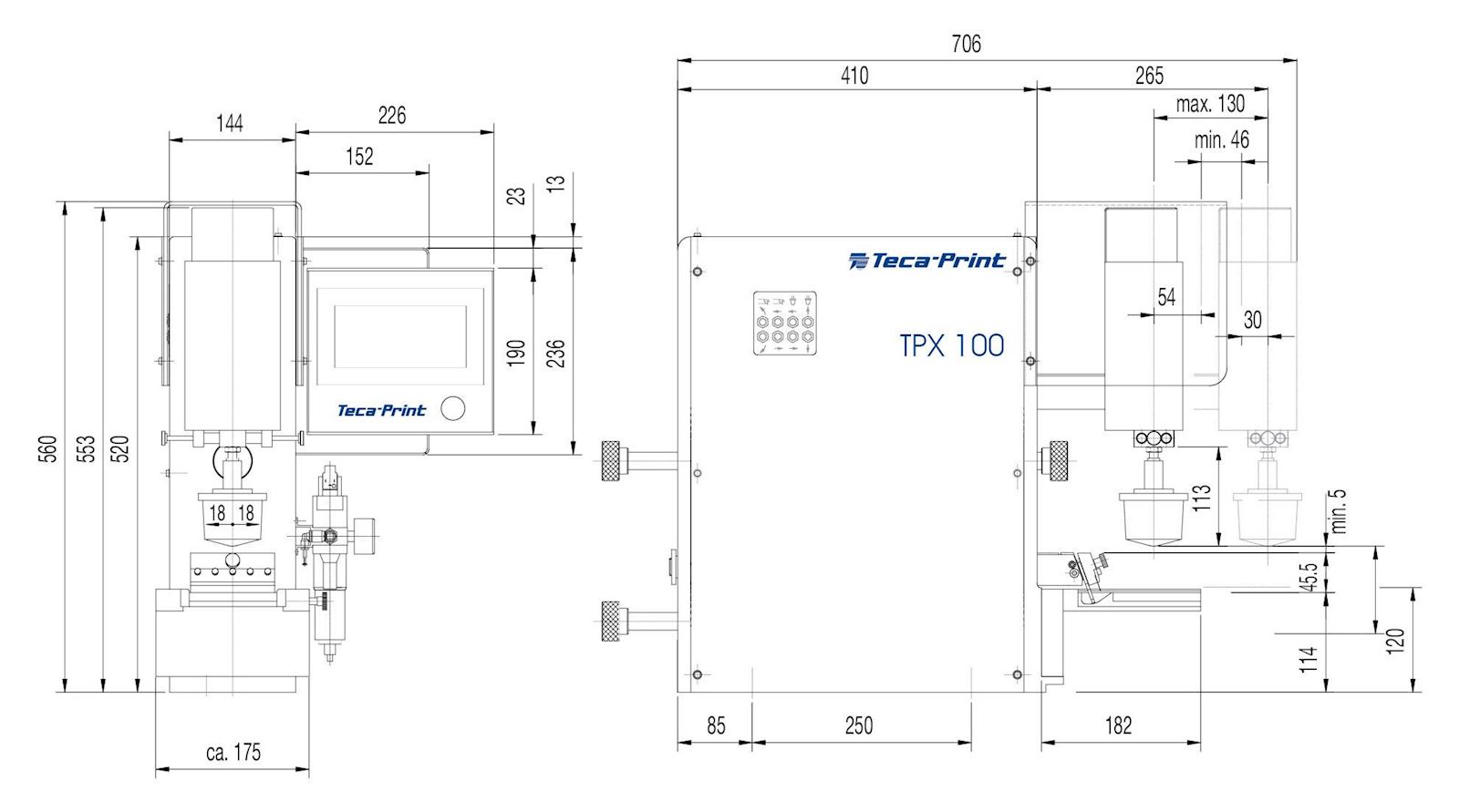

approx. 30 kg without base - Dimensions (WxHxD): 380 x 560 x 762 mm

Wijzig taal

Wijzig taal