Customised and innovative – complete automated systems from the technology leader in pad printing

Pad printing is a traditional printing process, but at the same time offers an infinite variety of innovative possibilities for the most diverse applications. For over 50 years, we have played a decisive role in the development of pad printing. New technologies on the market are consistently implemented and integrated into our machines and systems. This means that today we can offer you not only the machines for pad printing themselves, but also complete and customised solutions for your application. On request with automatic feeding and unloading, vision systems, systems for achieving optimum ambient conditions and, of course, with innovative software options.

Feeding – manual or automated? The choice is yours!

Teca-Print offers you the right feeder for your products depending on your requirements. Depending on the desired output, the properties of your products and the way in which your parts are supplied, we design and build the appropriate feeder.

Examples of automated feeders include spiral conveyors, step conveyors, jedec feeders, vibratory conveyors (anyfeeders), centrifuges or other separating conveyors. In many cases, a robot is used. We take the parts from your existing production line, e.g. after an injection moulding machine, and feed them to our printing system.

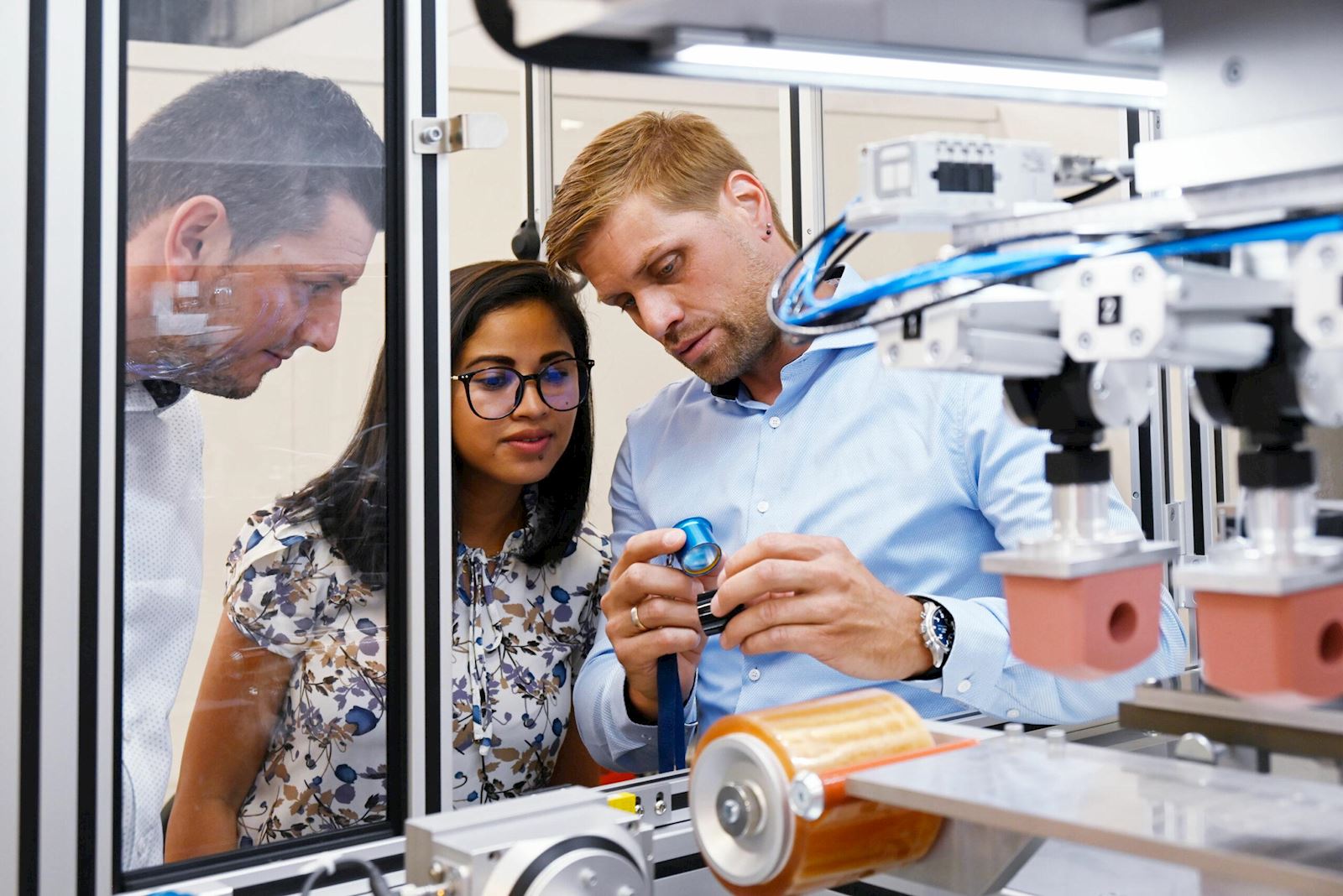

Printing – we integrate the perfect printing solution into your or our environment!

Printing is the centre of our printing systems. We can integrate individual machines into your production line or develop and build the entire line for you. In addition to machines, we also use flexible printing modules for installation in systems. In addition to the actual printing, our systems today also include pre-treatment, post-treatment, vision systems or devices that simplify the printing process and increase process stability. Such devices ensure, for example, a certain level of humidity or a constant cliché temperature.

A very important component of our systems is the software. Our machines and modules have state-of-the-art communication options with your production line. We also offer you options such as remote maintenance, remote maintenance plus and the myTeca-Print app. Benefit from higher productivity and optimised process reliability.

Regardless of whether you want to print in one colour or multiple colours, whether it is decorative or technical pad printing, we offer you the right solution for your application.

Unloading – we hand over after printing according to your wishes!

After printing and, if necessary, post-treatment, we hand over your parts according to your wishes and requirements. Both manual and automatic solutions are possible. An unloading robot transfers the parts to a conveyor belt or slide, for example, or places the parts in trays in the correct position.

For some applications, simple pneumatic ejectors are also suitable for further processing as bulk material or on a conveyor belt. The options are very versatile. We have the experience – you have the application. We look forward to developing a customised concept for you.

Wijzig taal

Wijzig taal